BREAD PRODUCTION LINES

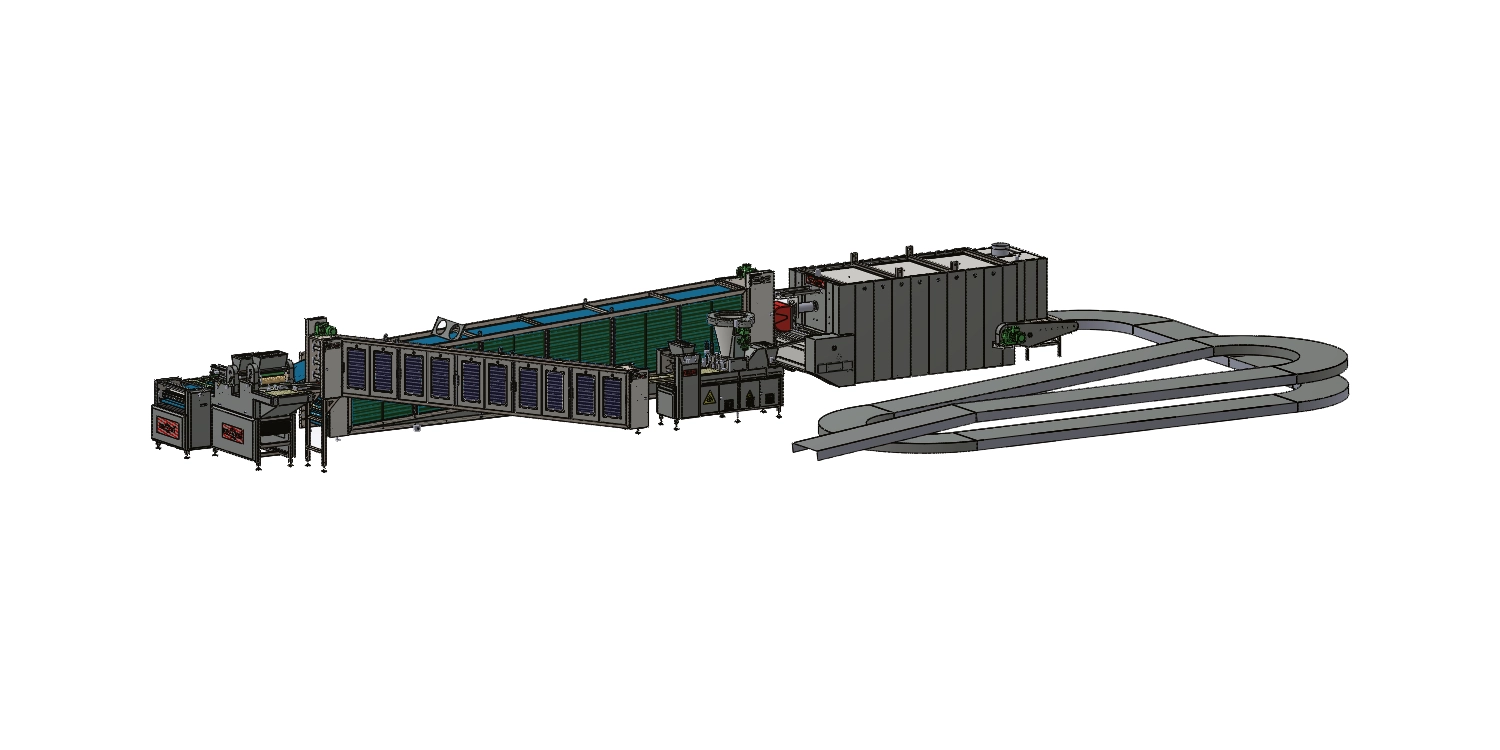

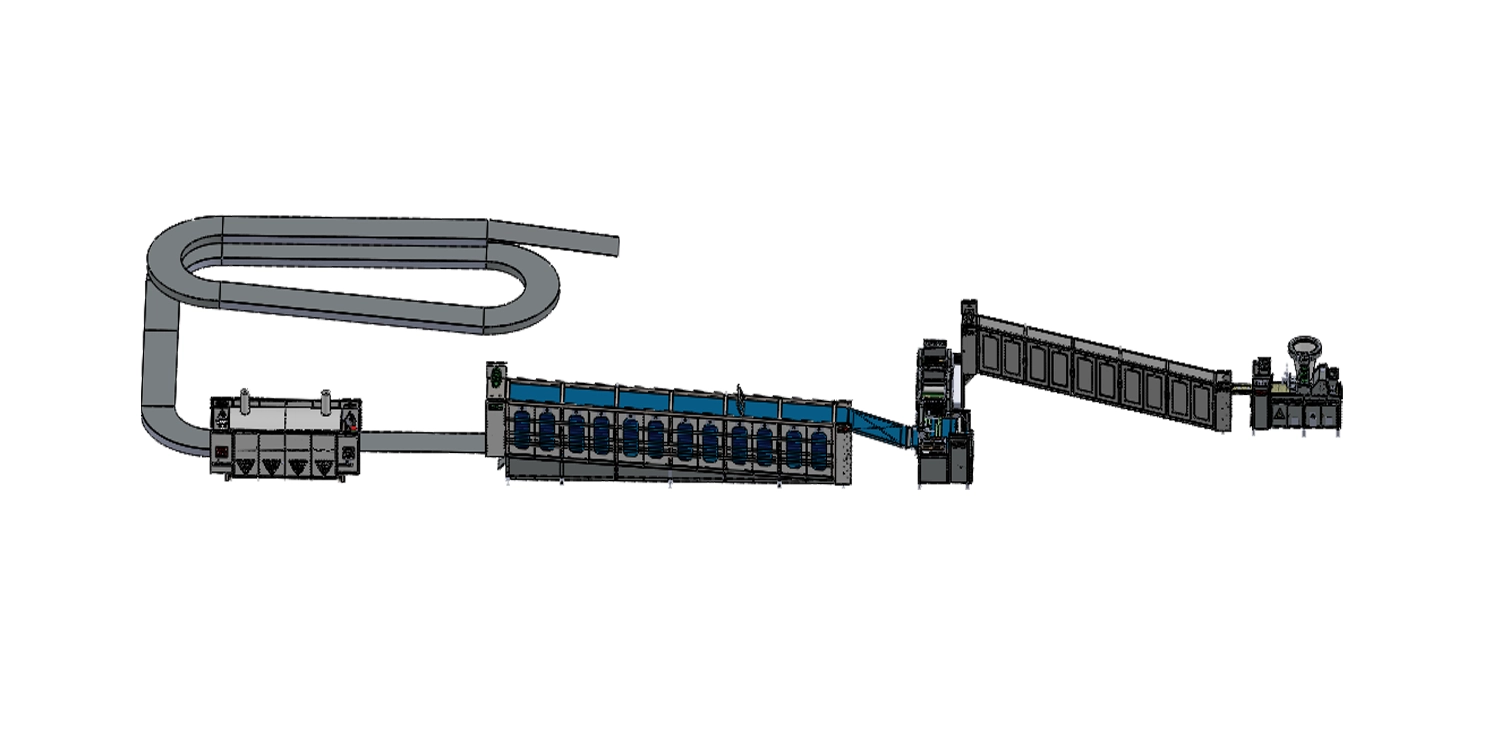

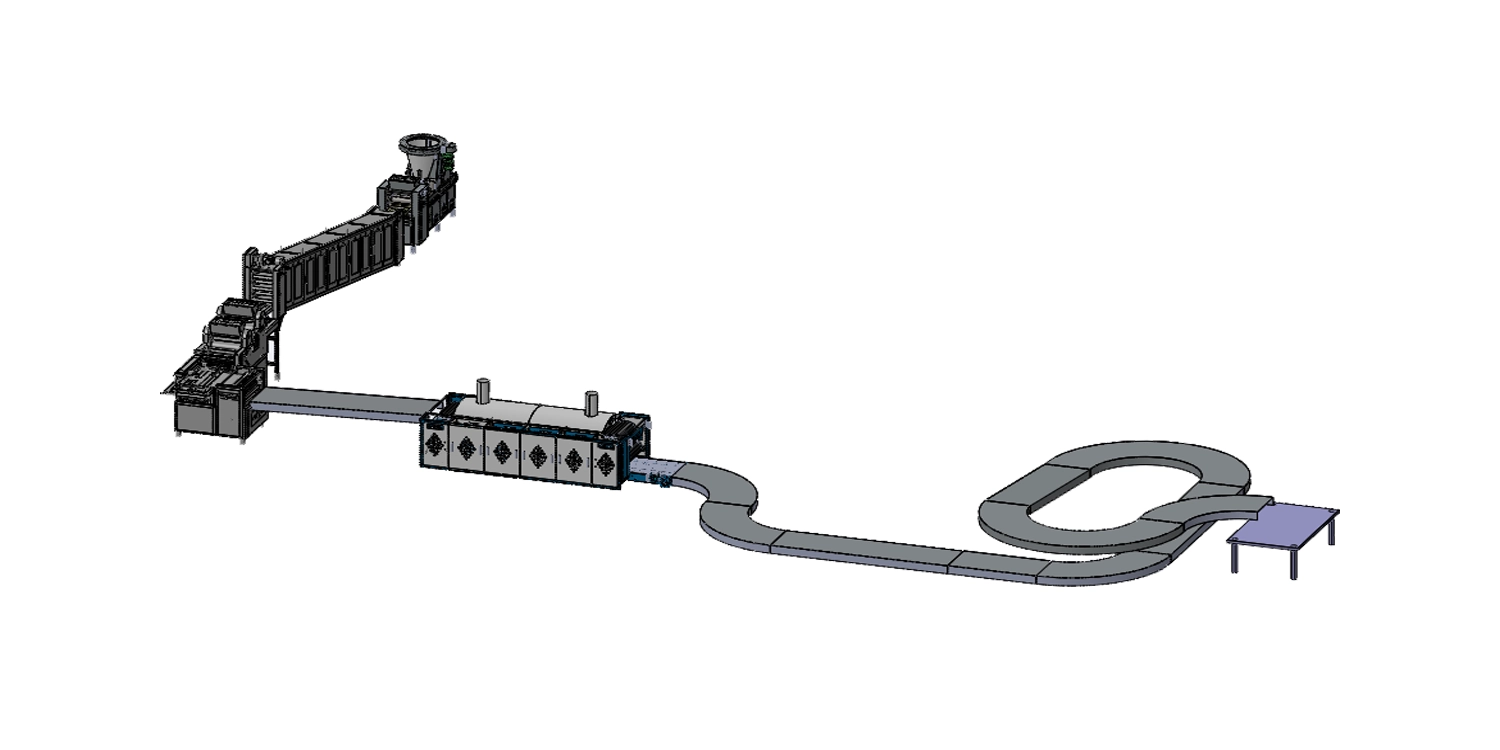

Lavash , Lahmajoun , Arabic & Lebanese Pita , Pocket Pita , Tortilla , Pizza and More…

PROFESSIONAL

ENGINEERING SERVICE

60-90 DAYS

delivery time

FREE

INSTALLATION

25-30 PCS

SPARE PARTS SUPPORT

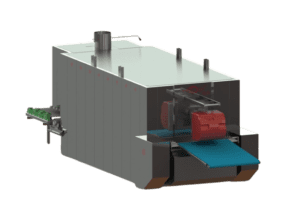

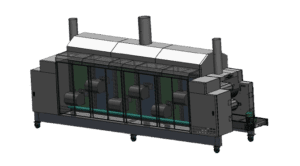

Pizza Tunnel Oven

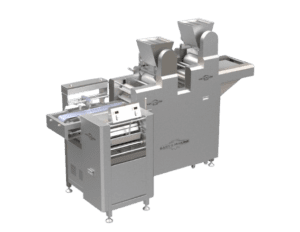

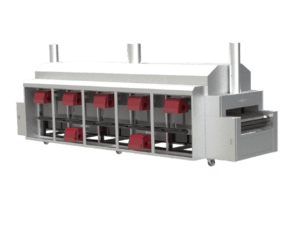

Tortilla Bread Line

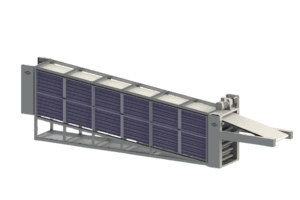

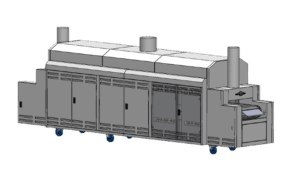

Our Bread Tunnel Ovens

Professional Baking Systems for Arabic Bread, Lavash, Pita, Tortilla, Lahmajoun and Pizza

Frequently Asked Questions

As Sarya Makine, we can divide our production into three classes:

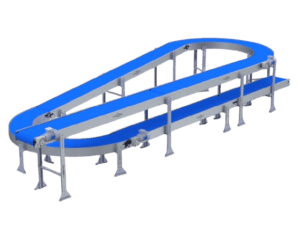

1. Bread Production Lines: We produce fully automatic bread production lines such as Arabic and Lebanese pita bread, thick pita, lavash, lahmacun and tortilla.

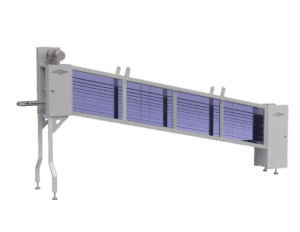

2- Dough Processing Machines: These machines include machines such as kneading, cutting, resting and rolling out yeast or unleavened dough. In addition, we have bread stacking and packaging systems for round bread types.

3: Our Filling and Packaging and Other Food Processing Machines: We manufacture filling machines for pulses, flour and liquid products. In addition, we manufacture special production machines such as oily/fat-free chips and pasta production machines.

You can find certain standard capacities for our production line or machines on our product pages. When determining these capacities, the needs of the relevant markets and customer demands are taken into consideration. Apart from standard capacities, projects can be made according to special capacity needs requested by customers.

As Sarya Makine, we offer pre- and post-sales technical support for our entire production line and machines. In addition, all our projects are commissioned and installed free of charge at the customer’s production site on a turnkey basis after careful engineering work.

We request the production area sketch from our customers with whom we agree on all matters. According to the sketch information received, we inform the customer about the suitability of the relevant production line or machine for the production area. If the production area is not suitable, we indicate it from the beginning. If the production area is suitable, after the sales contract and prepayment are received, our engineers position the best layout plan in 3D computer environment under the control of our customers. Following this process, we start production after receiving the final approval from our customer.

The final control and testing of the production line or machine is carried out in our factory. Following these procedures, the shipping process is started by obtaining test approval from our customer. It is our customer’s responsibility to obtain shipping freight quotes and arrange vehicles. However, our company can still get freight (shipping) offers for our customers from relevant places. The production line or machines are prepared separately for transportation, with their electrical systems ready and disassembled. It is loaded and sent to the relevant vehicles by our company.

Shipping

International To All Countries

After-Sales Support

During and After Warranty

Installation

Free and By Our Teams

© Subscribe to Our Youtube Channel

Türkçe

Türkçe العربية

العربية Русский

Русский