PRODUCT INFORMATION

Learn More About Tunnel Oven Machines

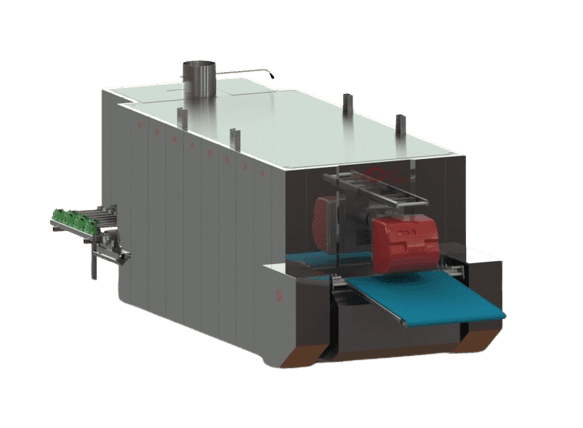

SARYA 800 series Industrial Bread tunnel oven is a type of ovens in which bread and other bakery products are produced on an industrial scale. These furnaces are generally designed in the form of a tunnel and are used in industrial furnaces. Bread tunnel ovens are designed to bake bread and similar products in a continuous production line.

These types of ovens process bread dough or other bakery products by moving them inside the oven, usually via a conveyor belt or conveyor system. The oven is designed to cook products at a certain temperature and time. As the products continuously move through the tunnel, they go through the desired cooking or baking process.

Bread tunnel ovens are generally used in industrial bakeries to produce high amounts of bread. These ovens ensure that bread is baked homogeneously and production is continuous. They also help optimize production processes with their ability to control temperature and cooking time. These ovens are preferred in the bread industry to ensure efficiency and bake large quantities of products.

For capacity and details, visit the technical specifications pages above.

Bread tunnel ovens are special types of ovens used for industrial bread production and have many advantages. Some of the benefits are:

High Capacity: Industrial tunnel ovens generally have a large capacity. They can operate on a continuous production line and process large quantities of bread or baked goods simultaneously.

Continuous Production: Tunnel ovens continuously pass the products through the oven with the help of a conveyor belt or conveyor system. This ensures an uninterrupted production process.

Homogeneous Baking: Bread tunnel ovens bake bread homogeneously thanks to the temperature and humidity control inside. This helps maintain the quality and consistency of the products.

Advanced Control Systems: These ovens are generally equipped with advanced control systems. Parameters such as temperature, humidity and cooking time can be adjusted precisely, allowing to optimize the quality of the products.

Efficiency: Industrial tunnel furnaces provide energy and time efficiency thanks to their ability to reach high temperatures and continuous operation.

Customizability: Manufacturers can customize these ovens according to different product needs. Appropriate adjustments can be made for different types of bread or baked goods.

Automation and Labor Saving: It can reduce labor costs thanks to continuous production. These ovens usually have automatic operation features and can keep human intervention to a minimum.

Bread tunnel ovens help large-scale bread producers optimize business processes by increasing efficiency while maintaining quality.

Capacity: The capacity of the oven to process how much bread or baked goods it can handle at the same time is an important factor affecting the price. Larger capacity ovens generally carry higher price tags.

Extras and Support Services: Factors such as warranty period, after-sales support, spare parts supply may also affect prices.

Need for Customization: If the oven needs to be customized to certain features or functions, this can often increase the price.

Türkçe

Türkçe العربية

العربية Русский

Русский