PRODUCT INFORMATION

Learn More About Bread Cooling Machines

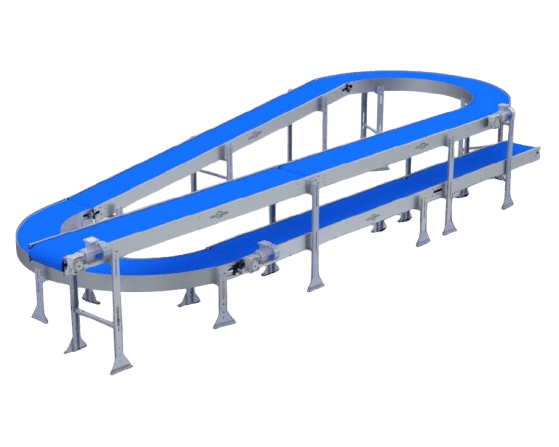

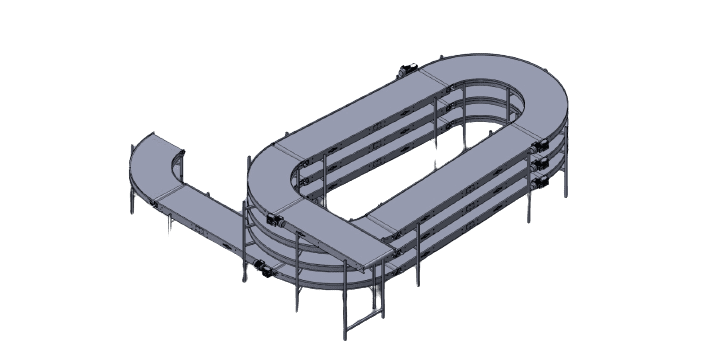

SARYA 900 series Industrial bread cooling belt is a type of equipment used in businesses producing bread on a large scale. It is a system used to cool the hot bread coming out of the bakery ovens. This system is generally designed as a conveyor belt or conveyor system.

Breads may be hot after coming out of the oven and may not be suitable for direct packaging or storage. At this point, the industrial bread cooling belt comes into play. After the bread comes out of the oven, it is placed on this cooling belt and left to cool for a certain period of time. This process ensures that the inner and outer parts of the bread cool down homogeneously.

Bread cooling belt is generally a system supported by air circulation. This system helps the breads cool quickly. Breads are carried on this belt, cooled under air flow, and then can be transferred to the storage or packaging stage.

Industrial bread cooling belts are important equipment that are used integrated with ovens in factories producing bread and are a part of the production line. They are used to preserve the quality of bread and ensure that they are stored at the appropriate temperature.

For capacity and details, visit the technical specifications pages above.

Industrial bread cooling belt has many benefits. Some of them are:

Preserving Bread Quality: Rapid cooling of hot bread ensures homogeneous cooling of the inner and outer parts. This preserves the quality of the breads and prevents unwanted moisture formation.

Continuity of Production Processes: Industrial bread cooling belt ensures continuity in the production line by rapidly cooling the bread. Rapid cooling of breads makes them suitable for packaging or storage stages.

Efficiency: Cooling of bread increases efficiency in production processes. Cold breads can be packaged or stored more quickly, which can improve the overall efficiency of the business.

Labor Saving: These systems, which can operate automatically, can reduce labor costs. Compared to manual cooling, there is less need for personnel intervention.

Hygiene: Industrial bread cooling belt allows bread to cool in a hygienic environment. This ensures that the products are stored in hygienic conditions.

Speed and Reliability: The automatic cooling process ensures that the bread cools quickly and reliably. This ensures faster and more reliable work processes on the production line.

Industrial bread cooling belts are indispensable equipment for businesses engaged in large-scale bread production, making production processes efficient and orderly while preserving the quality of bread.

Industrial bread cooling belt prices may vary depending on various factors. These factors include equipment features, capacity, technical specifications, material quality and additional functions. Some important factors affecting prices are:

Capacity: The capacity of how much bread the cooling belt can process at the same time is an important factor affecting the price. Higher capacity or larger size tapes generally cost more.

Technology and Features: The technological features of the cooling band, control systems, automation levels and additional functions it provides affect the price. Tapes with more advanced and customizable features can often cost more.

Size and Customization: Tapes of different sizes or customized features may affect prices.

Extra Services and Warranty: Some manufacturers offer additional services such as installation, warranty period, after-sales support, spare parts supply. This may also affect prices.

Pricing is often specific to a particular manufacturer or vendor and may vary with different market conditions. It is important to find the solution that best suits your needs and budget by comparing bread cooling belts with different features. It may be useful to contact manufacturers or sellers to get detailed information about pricing and purchasing process.

.

Türkçe

Türkçe العربية

العربية Русский

Русский