The Great Revolution in Bread Packing

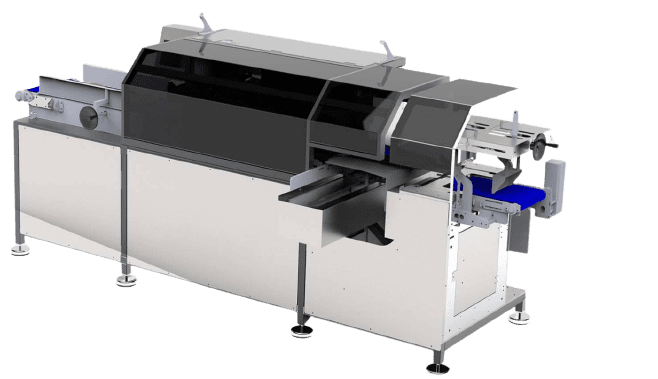

Meet Our Automated Packaging Machine

Customizable full automatic arabic and lebanese pita and lavash bread packaging. Get an offer now

See Technical SpecificationsOur Packaging Machine Video

PRODUCT INFORMATION

Learn More About Bread Packaging Machines

SARYA 1002 series Industrial bread packaging machine is a machine that automatically arabic pita, lebanese pita and lavash packages bread, generally used in large-scale bread production facilities. Such machines are designed to speed up production processes, reduce labor costs and make packaging operations more hygienic and effective. Industrial bread packaging machines are designed to package a variety of bread types, sizes and shapes.

Some features may include:

Automation: Industrial bread packaging machines are generally automatic, meaning they pick the bread, pack it, and even seal the packages.

Speed and Efficiency: These machines can often operate at high speeds and can be integrated into continuous production lines so that large quantities of bread can be packaged quickly.

Hygiene: Industrial machines are generally made of hygienic materials such as stainless steel and have designs that facilitate cleaning processes.

Such machines are used in bakeries, bakery facilities, large food production facilities and similar places. Industrial bread packaging machines can help manufacturers optimize their business processes, giving them the advantage of bringing their products to market more quickly and effectively.

Industrial bread packaging machines are important devices used in large-scale bread production facilities. Some benefits of these machines may be:

Efficiency Increase: Industrial bread packaging machines speed up packaging processes and make large amounts of bread production more efficient, thanks to their automatic operating features.

Manpower Saving: Automated processes require less labor than manual packaging processes. This can reduce the personnel costs of businesses.

Product Consistency: Industrial packaging machines ensure consistent packaging of products. This provides the advantage of providing customers with more reliable and standardized products.

Hygiene and Quality Control: Made of stainless steel or other hygienic materials, these machines meet hygiene standards and make packaging processes more controlled.

Product Stays Fresh for a Long Time: Airtight packaging can help breads stay fresh and have a long shelf life. This provides advantages in the storage and distribution processes of products.

Flexibility: Industrial bread packaging machines generally have the ability to package breads of different sizes and shapes. This provides manufacturers with the flexibility to respond to various customer demands.

Fast Packaging: Machines that can operate at high speeds can perform fast packaging operations in facilities that produce large quantities of bread.

These benefits help industrial bread packaging machines provide businesses with a competitive advantage by offering more effective production and cost advantages.

Industrial bread packaging machine prices may vary depending on various factors. Here are some of these factors:

Capacity: The packaging capacity of the machine, that is, the amount of bread it can package in one hour, usually affects the price. High capacity machines are generally more expensive.

Automation Level: The difference between automatic and semi-automatic machines is an important factor that determines the price. Fully automatic machines are generally more expensive, but can reduce operating costs and increase efficiency.

Packaging Types: Different packaging options and sizes supported by the machine affect the price. Machines with various packaging options are generally more expensive.

Quality and Durability: The material from which the machine is made, its quality and durability have a significant impact on the price. Machines that use durable materials such as stainless steel generally cost more.

Seller and Geographic Location: Sellers’ pricing policies and geographical location are other important factors that affect prices. Additionally, shipping costs are also an important factor.

The features of the machine to be purchased should be selected in line with the needs and budget of the business. Considering price-determining factors can help in making the right choice.

Türkçe

Türkçe العربية

العربية Русский

Русский