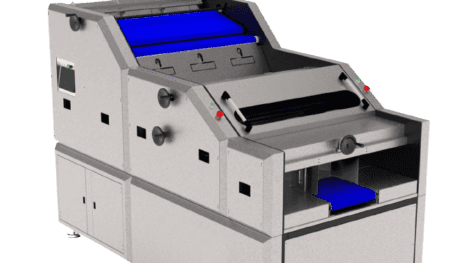

PRODUCT INFORMATION

Learn More About Bread Stacking Machine.

SARYA 1001 series industrial bread stacking machine is a machine generally used to automatically stack bread or other similar products. These types of machines are often used on production lines or large-scale bread production facilities. Bread stacking machines are often used on an industrial scale to stack, package or transport bread.

The working principle of the machine is to facilitate automatic packaging or transportation processes by collecting and stacking breads. This can reduce human intervention on the production line and make the process more efficient. Breads to be stacked can be sorted and stacked in different ways depending on the design of the machine.

Such machines, used in industrial enterprises to increase efficiency for bread production and packaging, can speed up production processes and reduce labor costs.

Productivity Increase: Bread stacking machines reduce manual labor by performing automatic stacking on the production line. This speeds up the production process and increases efficiency.

More Orderly and Hygienic Stacking: Machines generally stack bread to a certain standard and in an orderly manner. This allows products to be packaged or transported in a more orderly and hygienic manner.

Occupational Health and Safety: Automatic stacking reduces the need to manually carry heavy loads. This creates a positive impact in terms of worker health and safety.

Time Saving: Machines automatically stack bread, reducing human intervention and making the process faster. This saves time and speeds up the production process.

Less Labor Cost: It reduces labor costs by reducing the need for workers and automating the production process.

Product Quality and Consistency: Machines stack bread to a certain standard, which allows products to be packaged or transported more consistently. This can improve product quality.

Bread stacking machines are generally used in large-scale bread production facilities or industrial facilities. These machines optimize the production process and provide more efficient, regular and faster production.

Prices of bread stacking machines may vary depending on various factors. Prices are determined by several main factors:

Features and Capacity of the Machine: Features such as the capacity of the machine, the size of the breads to be stacked and the stacking speed affect the price. Higher capacity and faster machines can often be more expensive.

Technological Features: The technology and innovative features used affect the cost of the machine. For example, additional functions such as automatic adjustment features or integrated packaging systems can increase the price of the machines.

Production and Material Quality: The quality of the material from which the machine is made affects durability and performance. Machines using steel or similar high-quality materials can often be more expensive.

Market Conditions: Factors such as market demand, exchange rates, material costs and competition can affect the prices of machines.

Türkçe

Türkçe العربية

العربية Русский

Русский