PRODUCT INFORMATION

Learn More About Final Proofing Machines

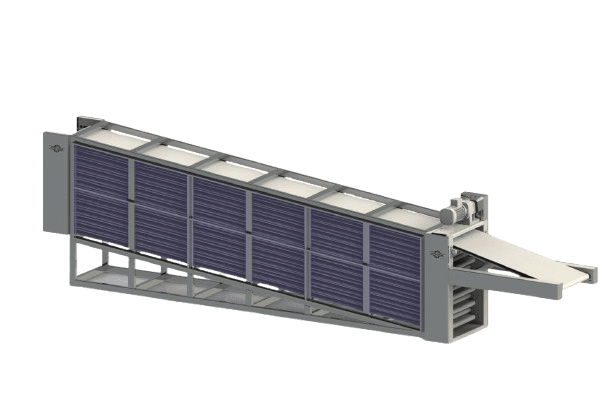

SARYA 700 series Industrial Final Dough Resting Machines are used to rest, ripen and prepare the dough for the processing process before rolling out the dough or shaping it. These machines allow the dough to rest, relax and gain elasticity under the desired conditions for a certain period of time.

Industrial rolled dough resting machines are equipment that generally works automatically or semi-automatically, controlling the resting time of the dough and factors such as temperature and humidity. This process is carried out in order to improve the quality of the dough and ensure that the final product cooks better, takes shape and has a superior taste.

Such machines may be various types of equipment used in the processing and preparation of rolled dough in industrial bakeries or bakery production facilities. They may have different designs, features and capacities depending on manufacturers and facilities.

For capacity and details, visit the technical specifications pages above.

-

Quality Improvement: Resting, maturing and gaining elasticity of the dough can improve the quality of the final product. Baked goods with better texture, taste and consistency can be obtained.

Even Resting Time: The machine ensures that the dough rests evenly throughout. This improves the homogeneous processing of the dough and the quality of the final product.

Adding Elasticity: Resting and maturing the dough increases its elasticity, making it easier to process. This allows the dough to take shape and rise better while baking in the oven.

Work Efficiency: Automated or semi-automatic systems reduce labor requirements and can increase efficiency in the production process.

Preservation of the Product: Rested dough generally takes a better shape and collapses less while baking, making the final product more visually appealing.

Product Quality and Freshness: Better dough maturation can increase the shelf life and freshness of baked goods.

Controlled Environment: The machine can control temperature, humidity and other parameters, allowing the dough to ripen under the desired conditions.

Production Continuity: In continuous production lines, the dough resting process can continue steadily and continuously, preserving the quality of the products.

Machine Capacity: The amount of dough the machine can process per hour is often a key factor affecting the price. Higher capacity machines can often be more expensive.

Design and Features: The design, features and functions of the machine determine the price. Machines with automatic or semi-automatic features, programmable controls, additional functions can generally be priced higher.

Application Field and Customization: In some cases, specially designed, customized or specially functional machines may be requested. In this case, the prices of the machines may increase.

Production and Supply Costs: Factors such as the cost of raw materials, production process and market conditions can affect machine prices.

Industrial rolled dough proofing machine prices can often vary depending on the specific supplier or manufacturer. Different pricing options can be offered according to customer needs, demands and budget.

Türkçe

Türkçe العربية

العربية Русский

Русский