The working principle and operation of this production line is as follows:

Dough Preparation:

At this stage, flour, water, yeast, salt and other ingredients suitable for lavash and pita bread are mixed. This mixture is kneaded to obtain dough. And the kneaded dough is covered and the first fermentation process is achieved.

Dough Cutting and Sheeting :

To obtain a certain shape and size, the kneaded dough is cut in the desired weight on the cutting machine and opened in the desired dimensions on the rolling machine.

Fermentation:

The shaped dough balls are left to ferment for a certain period of time. This process is important for fermentation and volume gain of the dough.

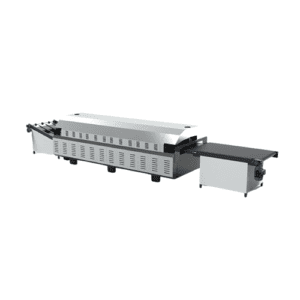

Cooking:

Following fermentation, the dough is usually baked in ovens at high temperatures. This allows the dough to rise and take on a bread consistency.

Cooling and Packaging:

The baked bread is cooled and then packaged. This stage ensures that the product is ready for storage and distribution.

Each bread production line design can vary depending on a particular producer’s needs, production volume and the types of products it will produce.

What is an industrial Lavash Bread Machine?

Sarya 100 industrial lavash machine is a large-scale device generally used in commercial enterprises such as restaurants, bakeries, large dining halls and food production facilities. Such machines are designed to produce large quantities of lavash and are usually optimized for continuous or semi-continuous production.

Sarya 100 industrial lavash machines are generally powered by electricity and have a series of processes in which the dough is automatically fed, rolled out, cut and baked. These machines provide high efficiency and speed, allowing large quantities of lavash to be produced quickly.

Sarya 100 industrial lavash machines can be found in different sizes and capacities. While there are high-capacity machines for large businesses, smaller-scale models are available for smaller businesses or restaurants. These machines can be equipped with various features according to the needs and production demands of businesses.

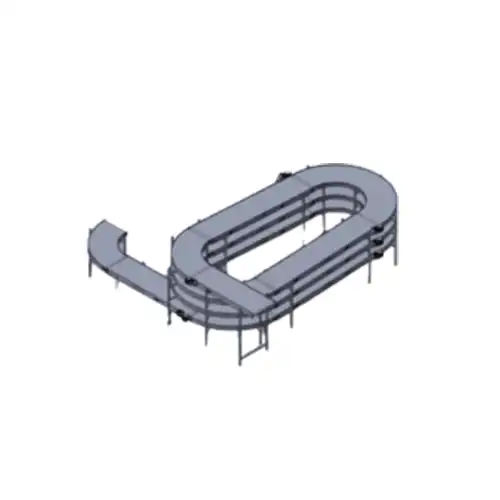

What is Sarya 100 Industrial Lavash Production Line? What Machines Are Included?

Industrial lavash production line is an automatic production system that includes a set of machines and equipment designed for large-scale lavash production. This production line is generally used in industrial kitchens, bakeries, large dining halls and food production facilities.

An industrial lavash production line usually includes the following components:

Dough preparation equipment: This equipment is used to prepare the dough. Equipment such as dough mixers, dough rolling machines and dough cutting machines can be found.

Automatic dough rolling and shaping machines: These machines enable the dough to be rolled out to a certain thickness and then shaped into lavash. This process is usually completely automatic and does not require human intervention.

Cooking equipment: Specially designed ovens or baking machines are used to bake lavash. These machines generally have features that can reach high temperatures and provide fast cooking.

Cooling and packaging equipment: Cooked lavash is processed with equipment designed for cooling and packaging. The cooling process allows the lavash to cool quickly and then be packaged.

Industrial lavash production lines enable the rapid production of large quantities of lavash, providing high efficiency, automation and consistency. These systems are used to meet the demands of food businesses and optimize production processes.

What Machines Are in the Lavash Production Line:

What are the General Features of Sarya 100 Production Line?

Sarya 100 production line is a fully automatic system. It includes dough preparation, processing, resting, cooking and cooling machines. Sarya 100 production line has a production capacity of 2000-2500 pieces of lavash bread per hour. You can see all the technical details above. You can contact us for more detailed information and prices.

What machines are in this production line:

Dough Kneading Machine

At this stage, flour, water, yeast, salt and other ingredients suitable for lavash and pita bread are mixed. Dough is obtained by kneading this mixture. And the kneaded dough is covered and the first fermentation process is carried out.

Türkçe

Türkçe العربية

العربية Русский

Русский