PRODUCT INFORMATION

Learn More About Dough Rolling Machines

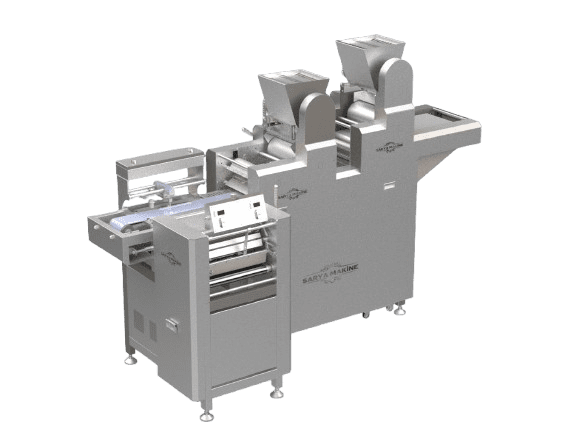

SARYA 600 series Industrial dough rolling machine is a kitchen equipment generally used for rolling out large amounts of dough quickly and regularly. These types of machines are used in patisseries, bakeries, hotels and food production facilities.

These machines can generally come in different sizes and features. Dough rolling machines are used to roll out dough to a certain thickness and width. For example, it can be used for various culinary processes such as pizza dough, bread dough, pastries.

These machines can generally operate manually or automatically. Automatic dough rolling machines usually work with engine power and can be adjusted to roll out the dough to the desired thickness. Some models have different speed and width settings.

Industrial dough rolling machines enable businesses to roll out large amounts of dough quickly, efficiently and in standard sizes, saving time and labor for businesses. These machines also support consistency and quality standards between products by ensuring the dough is rolled out homogeneously.

For capacity and details, visit the technical specifications pages above.

The dough rolling machine provides a number of benefits when used in industrial kitchens or food production facilities:

Time Saving: The machine enables rolling out large amounts of dough quickly and regularly. This shortens labor time and saves time for the business.

Regular and Standard Rolling: The machine allows the dough to be rolled out to a certain thickness and width. This maintains consistency and standards across products.

Saving Labor: Automatic dough rolling machines allow staff to focus on other tasks. It requires less labor than manual opening.

Easy to Use and Adjustability: Allows the dough to be rolled out to the desired thickness. Some machines have different speed and width settings, suitable for various dough types.

Increasing Product Quality: The machine enables the dough to be rolled out homogeneously, which helps the final products achieve a better structure, consistency and taste.

Hygiene and Cleanliness: Machines are generally made of easy-to-clean materials and are designed to meet hygiene standards.

Production Quantity and Scalability: Supports the production of large quantities of pastries and allows businesses to grow.

These benefits provide businesses with advantages such as efficiency, quality standardization and cost savings. Dough rolling machines play an important role in large-scale pastry production and are one of the indispensable equipment in industrial kitchens.

Industrial dough cutters are critical in large-scale production or commercial kitchens. These machines simplify processes, increase business efficiency and generally offer significant advantages to businesses.

Dough rolling machine prices may vary depending on several factors:

Machine Capacity: Prices may vary depending on dough processing capacity. Industrial size or larger capacity machines generally come at higher prices.

Features and Functions: Features of the machines, such as adjustability, speed options, opening in different thicknesses, etc. affect the price.

Production and Distribution Costs: Factors such as production costs, distribution and transportation can also affect prices. Imported machines may have additional costs such as customs duties and shipping costs.

Prices are typically set for a specific model, brand or feature set and may vary with a combination of these factors. When comparing prices, it is important to consider the features, performance and durability of the machines. When choosing an affordable machine, quality, features that suit your needs and the long-term performance of the machines should be taken into consideration.

Türkçe

Türkçe العربية

العربية Русский

Русский